How it works

The weld cleaning process and why we build our machines the way we do.

What is it and why is it the gold standard in finishing stainless steel?

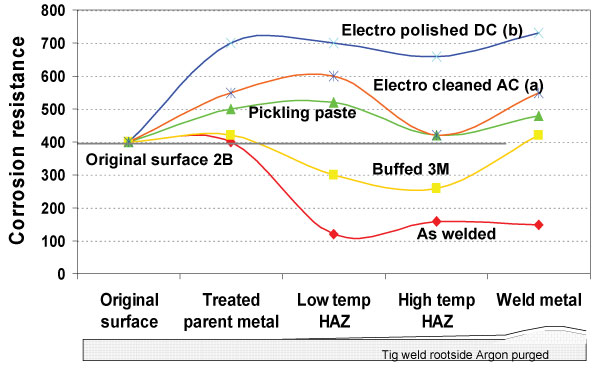

The best way to post-weld finish stainless steel is electropolishing, which is an electrochemical process using direct current (DC) that increases the density of chromium throughout the treated area (either the weld itself or the entire part).

The corrosion resistance of stainless steel arises from a chromium oxide film that forms a protective layer naturally on the surface of the steel. The oxide film is extremely thin but strongly adherent and chemically stable which is commonly referred to as ‘passive’. The film is formed when chromium in the metal reacts with the oxygen in the air.

The high temperature of welding results in severe chromium depletion, not only at the weld surface but throughout the greater heat affected zone (HAZ). Therefore, removing surface material such as oxide scale is only half the job, as the weld area is still chromium depleted relative to the parent stainless steel.

Critically, when the weld is depleted of chromium its corrosion resistance is severely reduced. The weld is therefore vulnerable to surface corrosion which is often referred to as tea staining. This of course impacts among other things cosmetic appeal, one of the main reason it choosing stainless steel in the first place.

Electropolishing selectively dissolves the microscopic high points of the stainless and selectively removes iron so in turn increases the chromium density and creates a microscopically smother surface on which bacteria contaminates cannot bind or hide.

In the past electropolishing could only be performed by the immersion of the work piece in electrolyte solution, which isn’t always possible, practical or cost effective. With the EASYkleen range of machines which exclusively use a DC output (electropolishing), you can now post weld finish either in the factory or onsite due to the machines being highly portable, all while ensuring you are providing the most corrosion resistant finish you can achieve on stainless steel.

Once stainless steel has been electropolished, the surface cannot be bettered.

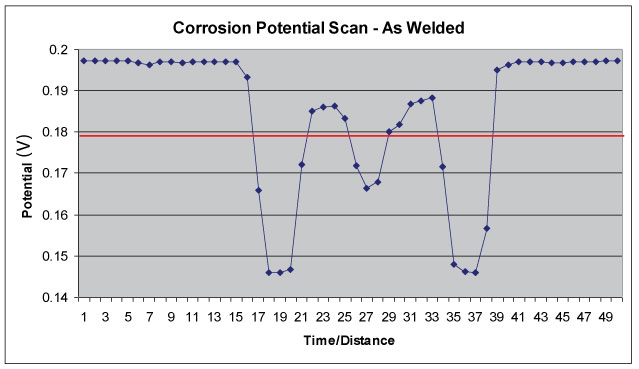

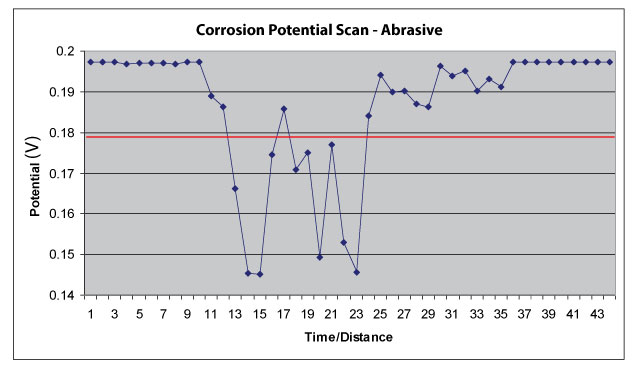

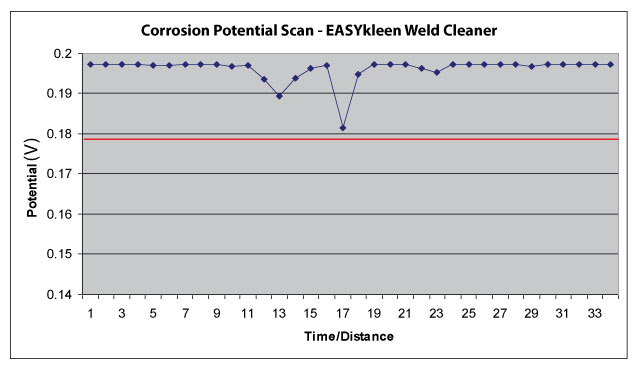

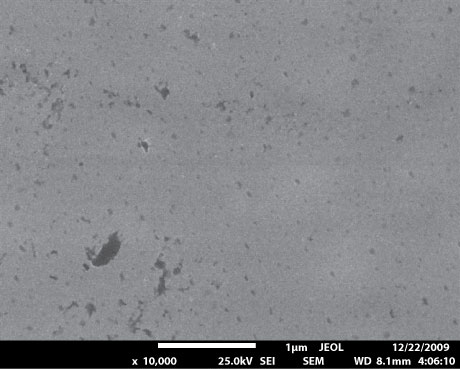

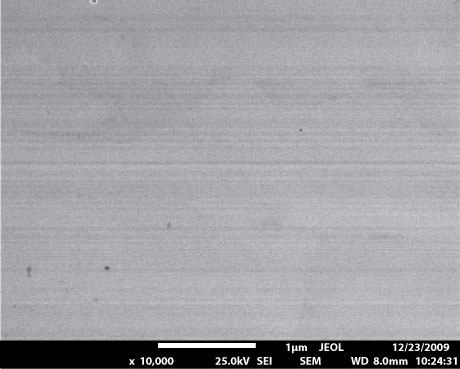

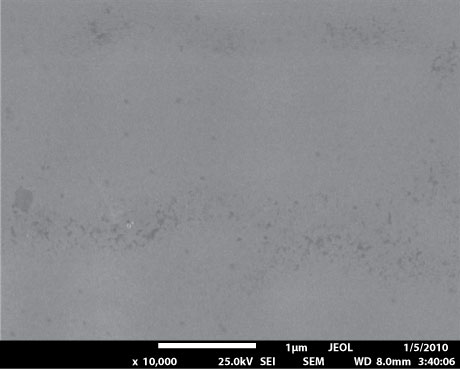

The below images are of the corrosion pitting potential of “As welded”, after abrasive finishing and after using an EASYkleen weld cleaner. Only the EASYkleen weld cleaner produces a result that is favourable to minizming corrosion potential.

When considering quality of finish, we need to also think about the morphology (shape/structure) of the surface. For stainless steel, the smoother the surface is, the less contamination (dirt, oils, salts etc.) can adhere, which drastically inhibits bacteria growth and foreign particle entrapment.

This gives maximum access to the oxygen required for a strong and continuous passive layer, dramatically improving the corrosion resistance process.

Surface finish is very irregular which allows contaminants stick or attach to the surface much easier which increases the pitting potential (corrosion).

This smoothing effect, whilst removing a very small amount of material also aids in removal of large grain boundaries which are usual susceptible to pitting (corrosion).

The conclusion is that of all post weld finishing methods tested, the use of a DC output weld cleaning machine, which uses the process of electro-polishing achieves the smoothest finish, will provide the best deterrent against pitting (corrosion).

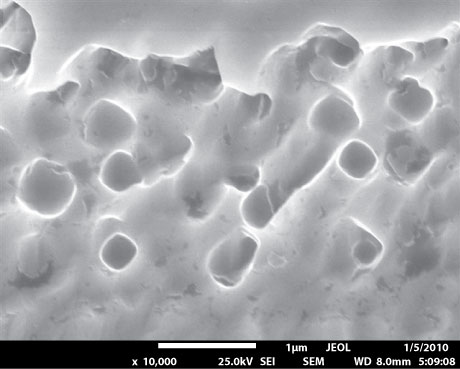

The images below are from a Scanning Electron Microscope and show a before and after of two welds, one cleaned using the EASYkleen Plus, whilst the other was cleaned using an AC “clean setting” output weld cleaner.

There are many weld cleaners in the market place these days, but we are not comparing apples with apples.

Unfortunately, it is quite difficult at times to find sufficient technical information on many of the weld cleaners out there.

One particular aspect we discuss with a potential customer is current output. Is the output of the machine alternating current (AC), direct current (DC), or can it switch between both?

Here at EASYkleen, we have only ever manufactured DC only output weld cleaning machines, and we’ll explain why –

Firstly, you can only truly electro-polish if you are using a DC output, and therefore receive all the benefits it has to offer. These include improved corrosion resistance up to or above the parent metal, inhibiting bacterial growth, and cosmetic appeal.

Secondly, cost saving. The AC cleaning process removes material from both sides (workpiece and brush electrode) equally due to the alternating of the current. One half cycle it is removing material from the workpiece, the other half cycle it is removing material from the brush electrode. This means that brush life is significantly reduced when using an AC output compared with that of DC. The DC process will still remove material from the brush electrode due to heating and arcing when the brush gets too dry, but it is at a significantly reduced amount. You are also not susceptible to the micro acring issue on DC compared to AC, as explained above.